The World of Press Tools: A Career Guide for Mechanical Engineers

June 13, 2024 2024-06-19 5:09The World of Press Tools: A Career Guide for Mechanical Engineers

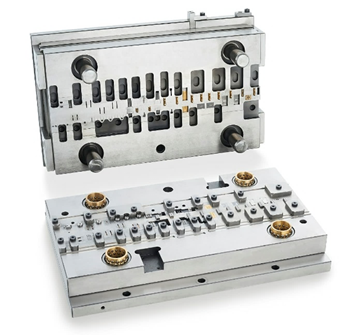

In the bustling world of manufacturing, a silent revolution unfolds beneath the surface. Press tools, the unsung heroes of this realm, toil tirelessly, shaping metal into intricate components with remarkable precision. Their influence transcends industry boundaries, weaving itself into the very fabric of our daily lives. From the gleaming car parts that propel us forward to the intricate circuits that power our devices, press tools leave their mark on a vast array of products. Here’s an industry

that has lot of potential for employment and can therefore be a lucrative and one of the best career options for graduates after B.E. Mechanical Engineering. This exploration delves into the diverse applications of these ingenious tools, revealing how they contribute to various sectors and ultimately become the backbone of the essential products that define our modern world.

Automotive Industry:

Looking to land a job in the automotive industry after your Mechanical Engineering degree? Consider specializing in press tool design! Press tools are the workhorses behind the scenes, shaping both the comfort and safety features of our cars. From crafting dashboards and door handles to producing life-saving airbag housings and reinforced door beams,

they play a vital role. But their influence goes even further, contributing to efficient engines and reduced emissions by forming exhaust system components like mufflers and catalytic converters. No wonder the automotive industry is one of the biggest employers for engineers with press tool design expertise! A postgraduate course in Tool Engineering or PG Diploma in Tool Design could be your key to unlocking a rewarding career in this dynamic field.

Electronics and Electrical Appliances:

Press tools are the unsung heroes of the electronics revolution, silently shaping the future behind the scenes. From electric vehicles to the devices in your pocket, their influence is undeniable. They’re responsible for crafting vital battery components like casings, terminals, and connectors, ensuring efficient power

delivery in everything from portable electronics to large-scale energy storage systems. But press tools go beyond just enabling innovation; they’re the thermal guardians of our gadgets, meticulously crafting heat sinks and spreaders that keep devices cool and functioning optimally.

This isn’t just about functionality, though. Press tools also play a crucial role in aesthetics. They’re the masterminds behind the sleek, durable casings of our smartphones and tablets, marrying intricate design with everyday protection. Mastering the art of press tool design through a postgraduate course in Tool Engineering could be your ticket to a fulfilling career at the forefront of technological advancement. Moreover, pursuing a PG Diploma in Tool Design can equip you with the specialized skills needed to excel in this field. The demand for skilled press tool engineers is high, and the rewards extend beyond a good salary. You’ll have the satisfaction of knowing your work contributes directly to the development of cutting-edge electronics, shaping the way we live, work, and connect with the world.

Aerospace and Defence:

From the soaring grace of airplanes to the cutting edge of spacecraft, press tools form the backbone of aerospace engineering. These precision tools meticulously shape critical components like wing ribs, fuselage panels, and empennage parts. Their work ensures both the aerodynamic efficiency that keeps

these machines aloft and the structural integrity that guarantees passenger safety. Press tools don’t just conquer the skies; they also safeguard national defence. Their meticulous craftsmanship produces precise components for missiles and missile systems, including guidance fins, rocket casings, and warhead enclosures. But their reach extends even further, playing a vital role in space exploration. Press tools help fabricate components for satellites, such as solar panels, antenna mounts, and payload enclosures. These components enable communication, navigation, and scientific missions beyond our atmosphere.

For a recent Mechanical Engineering graduate (B.E./B.Tech), specializing in press tool design can equip you with the skills to become a crucial player in the industry. Mastering this specialized skill positions you as a crucial player in shaping the future of flight and space exploration. Imagine a career where your work directly impacts the machines that conquer the skies, safeguard nations, and propel us towards the stars – that’s the reality for press tool engineers in aerospace.

Construction and Architecture:

Press tools are the invisible sculptors of our built environment, shaping everything from sleek facades to the sturdy bones of infrastructure. They craft metal panels and cladding systems, imbuing buildings with both aesthetic appeal and vital protection against the elements. Their influence goes beyond mere beautification, though. Press tools are instrumental in constructing

the very foundations of our transportation networks: bridges, tunnels, and railway tracks all rely on their precision. Even the finishing touches – intricate details like balustrades, grilles, and finials – are often brought to life by press tools, adding a touch of elegance and character to our world. The enduring relevance of press tools, evident in their continuous evolution, ensures their irreplaceable role in the future. For mechanical engineering graduates, this field presents a pathway to a rewarding career shaping the very fabric of our built environment.

Consumer Goods:

The enduring relevance of press tools lies in their adaptability. Unlike technologies susceptible to rapid obsolescence, press tools have undergone continuous refinement, solidifying their position as an essential cog in the manufacturing machine. This unwavering demand positions press tool engineering as a compelling career path for mechanical graduates.

Embarking on a PG Diploma in Tool Design equips mechanical graduates with the cutting-edge expertise and hands-on mastery required to thrive in this ever-evolving domain. It offers not only long-term job security but also the immense satisfaction of contributing to the creation of a vast array of products that enrich our daily lives.

The boundless versatility of press tools makes them indispensable across industries, shaping the products and innovations that fuel our modern world. From crafting intricate components for electric vehicles and sleek casings for smartphones to forging the backbone of aircrafts and everyday consumer goods, press tools empower the creation of the intricate and functional metal components that drive progress. By enrolling in PG Diploma in Tool Design specializing in press tool design, you can gain the skills necessary to contribute to this vital field.

Thinking of 2-year degree courses after diploma in mechanical engineering?

While diploma holders may not be eligible for direct entry into a 2-year postgraduate degree program, there are alternative educational pathways to consider. One option is to pursue post diploma programs, which provide specialized training in specific fields. Besides, another option is to pursue a B.E/B.Tech degree course through lateral entry after completing your diploma in mechanical engineering. Following this degree, you can then opt for a 1-year postgraduate diploma or a 2-year postgraduate degree in engineering.

Here is the list of top courses you can choose after a diploma in Mechanical Engineering:

- Post Diploma in Tool Design

- Post Diploma in Power Electronics

- Post Diploma in Embedded Systems and IOT

- Post Diploma in Industrial Automation

This ever-evolving landscape demands skilled engineers – particularly those with expertise in tool design and development – making it one of the most sought-after skillsets in the manufacturing industry. A career in press tool engineering offers Mechanical Engineering graduates the opportunity to be at the forefront of innovation, directly shaping the products that define our future.